Both bottle neck finish and cap size follow and use a uniform standard and convention to describe their screw thread sizes and styles. This standard was developed by the Glass Packaging Institute (GPI) and the Plastics Industry Association (SPI).

Understand Two Numbers:

The screw thread sizes and styles are usually represented by two numbers:

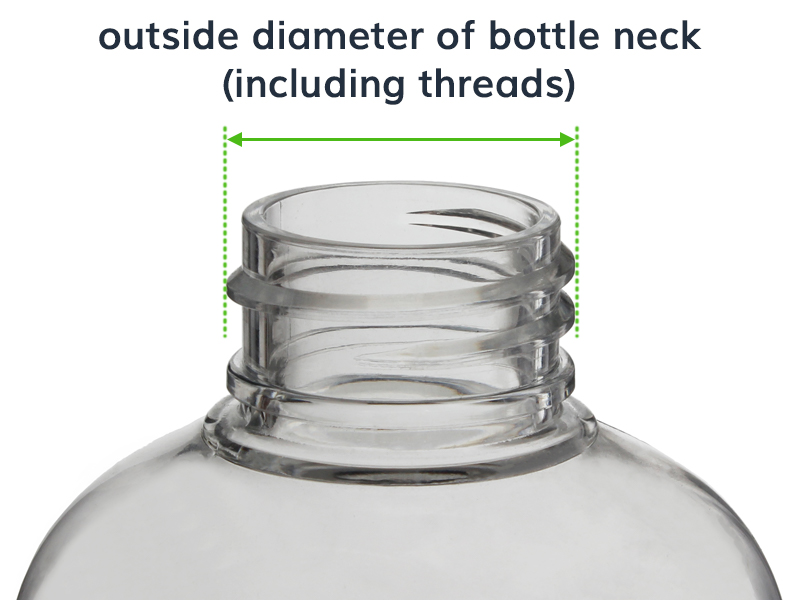

- The first number is a two-digit number referring to the outside diameter of bottle neck (including threads) or the inside diameter of cap (excluding threads) in millimeters.

The two pictures above show how to correctly measure a cap or bottle neck size, which requires the aid of a vernier caliper.

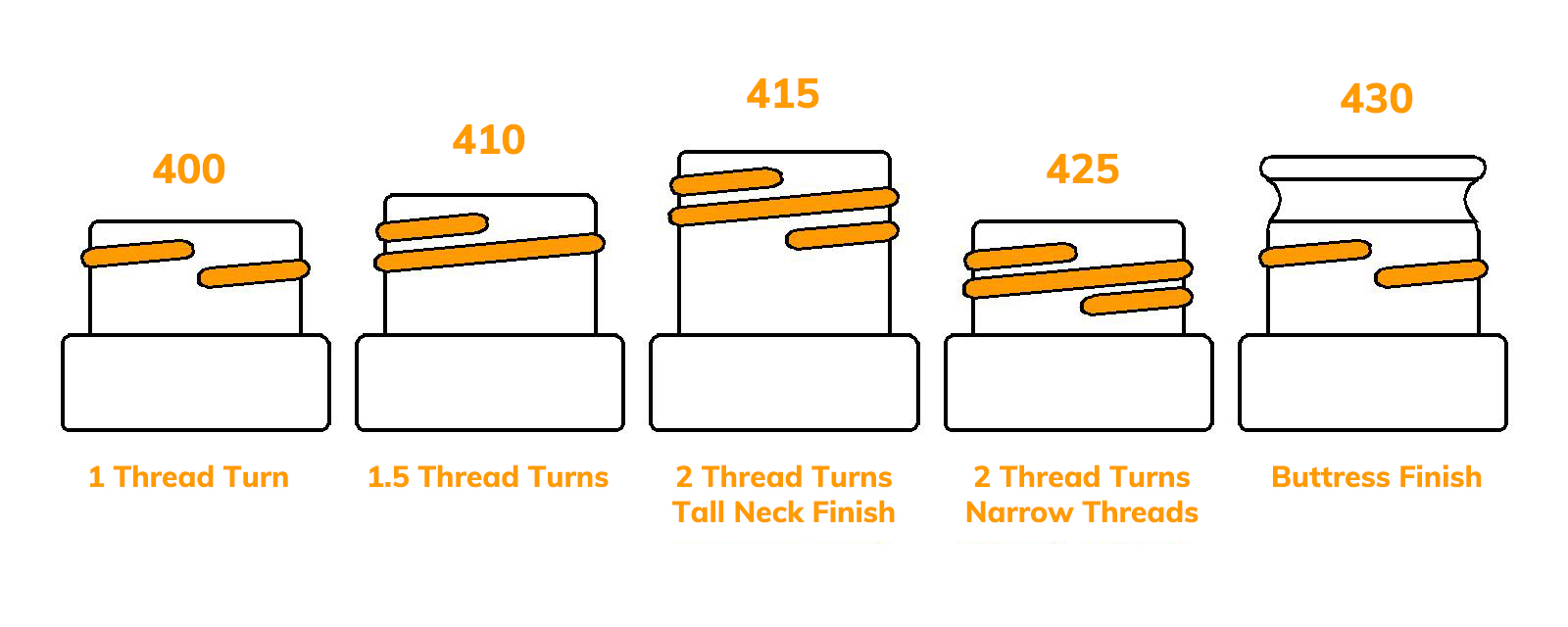

- The second number is three digits and refers to the thread height and style. There are many kinds of thread finish styles, here we list the most common thread styles for plastic bottles as follows.

The two numbers are usually separated by a forward slash or dash, such as 28/410 or 28-410.

Let’s take an example to help you better understand what’s said above, such as when we describe a bottle neck or cap size as 28/410:

- 28 means the outer diameter (including thread) of the bottle neck is 28mm. Or the inner diameter (excluding thread) of cap is 28mm.

- 410 represents 1.5 turns of thread and thread pattern around the mouth of the bottle (the second pattern in the picture above).

Learn More About Neck Finish

If you want to learn more about neck finish dimensions, please read on. The Complete neck finish dimensions include the following several measurements:

“T” dimension is the outside diameter of bottle neck including the thread. The tolerance range of the “T” dimension will determine the fit between the bottle and cap/closure.

“E” dimension is the outer diameter of the neck. The difference between the “E” and “T” dimensions divided by 2 determines the thread depth.

“I” dimension is inner diameter of bottle neck. It will impact the size of inner plug or liner/gasket of closure for a proper seal between bottle and cap/closure.

“S” dimension is the measurement from the top of the finish to the top edge of the first thread. The “S” dimension is the key factor which determines the amount of thread engagement between the bottle and cap/closure.

“H” dimension is the height of the neck finish. It is measured from the top of the neck to the point where the T dimension, extended down, intersects with the bottle’s shoulder.