Stretch Blowing Mould is for making PET Bottles on Two-Steps Stretch Blow Molding Machine.

If you have your own machine and prefer to produce bottles by yourself, we’re happy to provide the custom blow mold for you.

Let’s walk through the process

01

Basic information collection

First of all, we need information of you required bottle.

- raw material

- capacity / volume

- shape

- neck size

- weight

- dimension

- application

And your stretch blow molding machine information.

- if your machine Semi-automatic or Automatic?

- how many cavities of mold?

02

PET Bottle Design

The next step is to take the basic or idea and workup both 2D and 3D drawing detailing all the features. Following the drawings we then digitize the new bottle and render it out for a very close approximation of what the final bottle will look like.

03

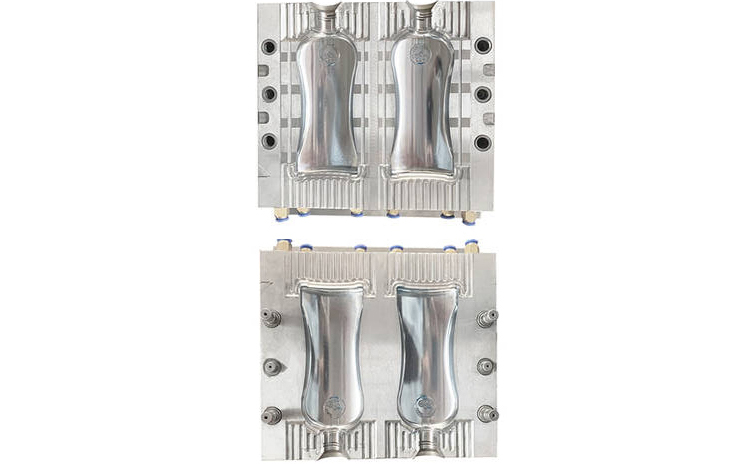

PET Blow Mould Design

After you confirm the bottle drawing or 3D sample, we start make mold design based on your stretch blow molding machine parameters.

04

Blow Mould Manufacturing

Next, we take the drawing to start mold manufacturing.

It usually takes 10 – 30 days to get the mold done.

05

Mould Trial

We will do the mold trial twice on our machine at least, and will send you final samples for final confirmation.

06

Mold Shipping Or Mass Production

The last step is deliver the mold to you. We can provide both of air & sea shipment service for you.

Or if you want the bottles / hollow products only, we can do the mass production for you.

Basic Specs of PET Bottle Blow Mould

| Mold Steel: | 4Cr13 / S136 |

| Cavity No.: | 1 to 8 cavities |

How to choose the correct Stretch Blow Mould?

It depends on your stretch blow molding machine type. There are two types of stretch blow molding machine as follows:

- Semi-Automatic Stretch Blow Molding Machine – it consists of one blower unit and one heating unit, it requires manual operation to feed the preform into the heating unit, then take the heated preform to the blower unit. The blow mold for semi-automatic machine is simple.

- Automatic Stretch Blow Molding Machine – it combines preform loading, heating and blowing with continuous action, no need manual operation. The blow mold for automatic machine requires a center distance data according to your machine.

Focused on Manufacturing High Quality Mold

Our focus is the quality. We always listen to the voice of market, our mission is to contribute to the development of the industry by creating innovation and supply reliable products.