If you’re looking for bottles or any plastic hollow products which are made of HDPE, LDPE, PP, PS, PETG, PVC, EVA, TPE, Nylon material etc, congrats! you’ve come to the right place.

Our factory manufactures over 100 sets of extrusion blow mould annually. We make sure our mold will be compatible with your extrusion blow moulding machine, no matter what brand your machine is.

Let’s walk through the process

01

Basic information collection

First of all, we need information of you required bottle.

- raw material

- capacity / volume

- shape

- neck size

- weight

- dimension

- application

And information of your extrusion blow molding machine.

- double station or single station

- die head number(mold cavity number)

- center distance of die head

- with or without Auto Deflashing

02

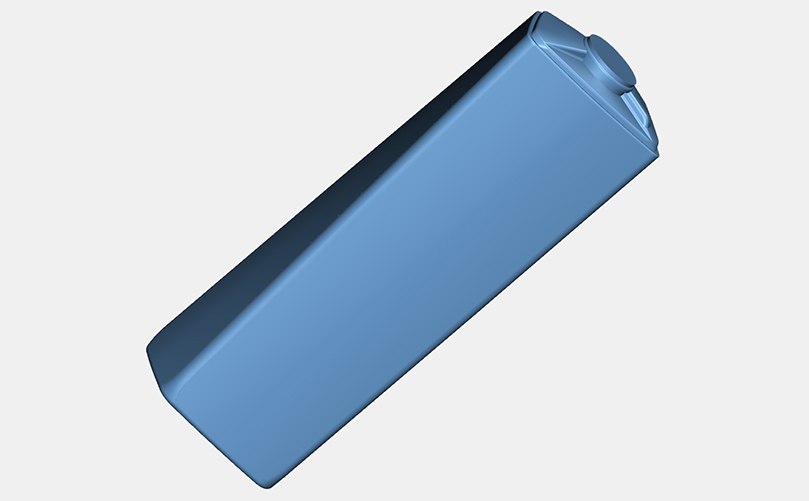

Bottle & Hollow Product Design

The next step is to take the basic or idea and workup both 2D and 3D drawing detailing all the features. Following the drawings we then digitize the new bottle and render it out for a very close approximation of what the final bottle will look like. This is where it really starts to come to life.

3D printed samples support

If you still got worries about 2D & 3D drawings, we can provide a 3D print sample and send to you via express, so that you can have a closer look of the final design and to ensure you will order the correct extrusion blow mould.

03

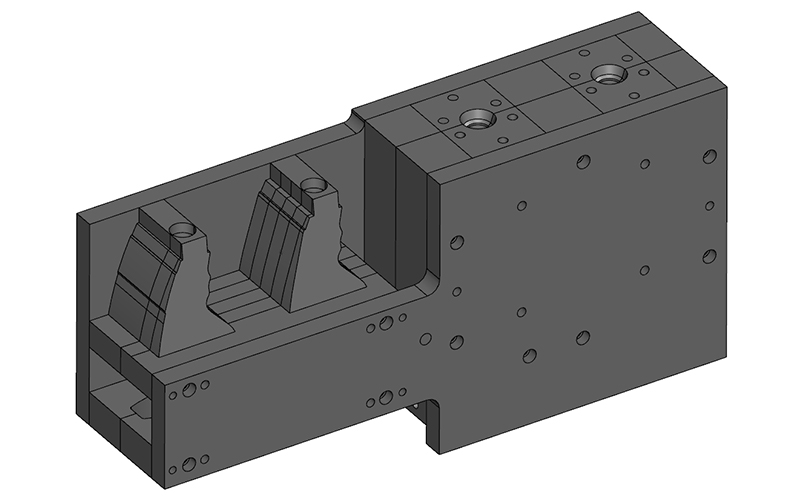

Extrusion Blow Mould Design

After you confirm the bottle drawing or 3D sample, we start make mold design based on your extrusion blow molding machine parameters.

04

Blow Mould Manufacturing

Next, we take the drawing to start mold manufacturing.

It usually takes 15 – 35 days to get the mold done.

05

Mould Trial

We will do the mold trial twice at least, and send you final samples for final confirmation. This is where your ideal bottle becomes a reality.

06

Mold Shipping Or Mass Production

The last step is deliver the mold to you. We can provide both of air & sea shipment service for you.

Or if you want the bottles / hollow products only, we can do the mass production for you.

Basic Specs of Extrusion Blow Mould

| Blowing Unit Steel: | 40Cr |

| Deflashing Unit Steel: | Aluminum |

| Neck Insert Steel: | 42CrMo |

| Frame Steel: | #45 |

| Cavity No.: | 1 to 8 cavities |

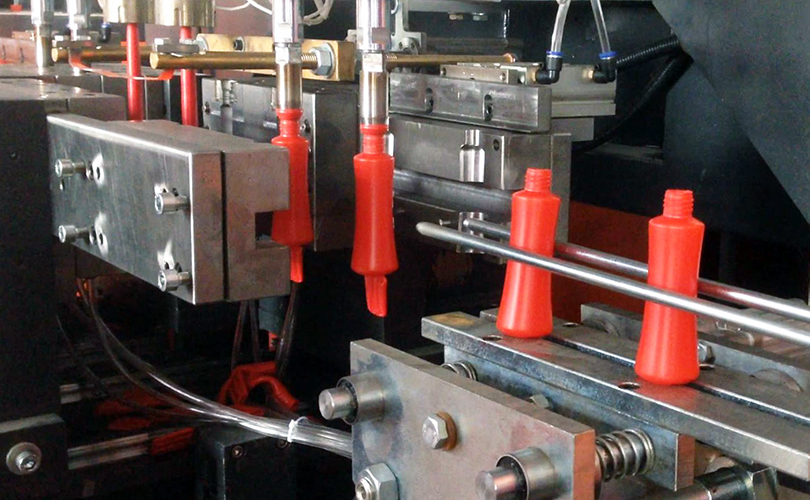

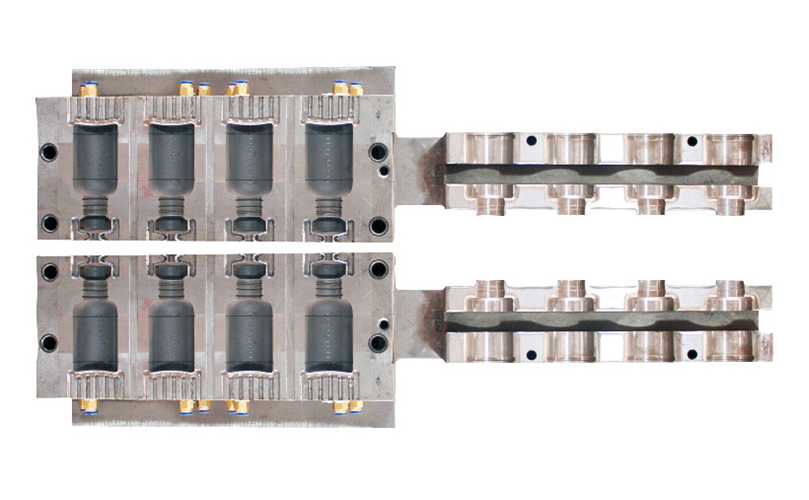

What is Auto-Deflashing to Extrusion Blowing Mold?

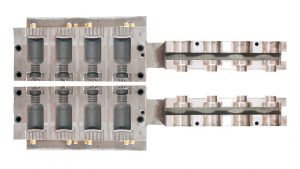

Auto-Deflashing means the bottle neck and bottom flash are automatically cut on extrusion blow molding machine.

A auto-deflashing blow mold consists of two parts:

- the blow molding part

- the deflashing part

Before you decide to buy blowing mold with auto-deflashing, please check if your extrusion molding machine support this function.

Check below photos to for your better understanding the difference between blow mold with and without Auto-Deflashing.

with Auto-Deflashing

Bottle neck & bottom deflash cut on machine

without Auto-Deflashing

Bottle neck & bottom deflash cut by manual or a separate device

Two types of Auto-Deflashing

There are two types of Auto-Dflashing, it depends on bottle mouth design. Both types are actuated by pneumatic cylinder.

Watch below videos to learn the difference.

In this type of auto deflashing, the bottle mouth top has a wide edge, and when bottle forming inside mold, it comes with a flash bubble on top. The cutting knife will rotate a circle to cut the whole bubble down.

In this type of auto deflashing, the bottle mouth top internal edge and inner wall are in same plane, when bottle forming inside mold, there is a open flash on top. The punch knife move forward to cut the flash down.

Focused on Manufacturing High Quality Mold

Our focus is the quality. We always listen to the voice of market, our mission is to contribute to the development of the industry by creating innovation and supply reliable products.