If you have your own injection molding machine, and prefer a cap mould to manufacture your own caps instead of buying finished caps, we are happy to manufacture the new mold for you. For almost all plastic caps we are selling on our site, the molds were made by ourselves.

The cap injection mold we can make for you include:

flip top cap mold, shampoo cap mold, condiments cap mold, disc top cap mold, screw cap mold, jar lid mold, child-resistant cap mold, tamper proof cap mold, pull-push cap mold, theft-proofing cap mold, easy tear cap mold, barrel cap mold, laundry detergent cap mold, cooking oil cap mold, wet tissue cap mold and so on.

Let’s walk through the process

01

Basic information collection

- cap usage

- neck size

- weight

- dimension

- sample photo

- injection machine model

02

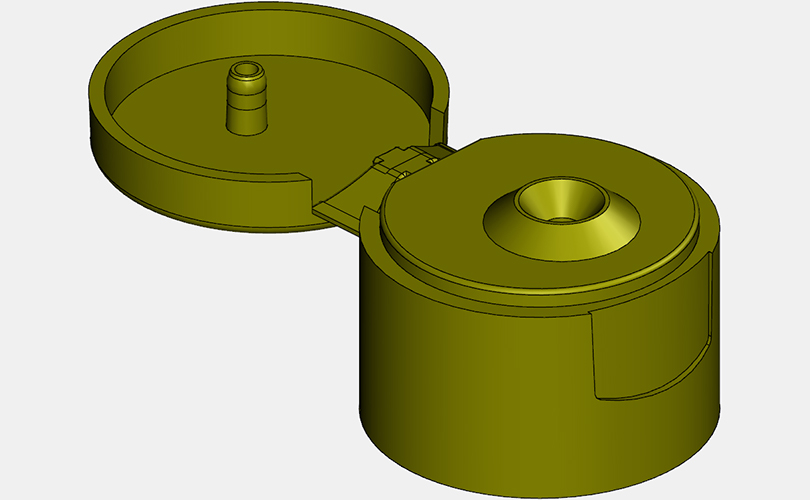

Bottle Cap Design

The next step is to take the basic or idea and workup both 2D and 3D drawing detailing all the features. Following the drawings we then digitize the new cap and render it out for a very close approximation of what the final cap will look like.

03

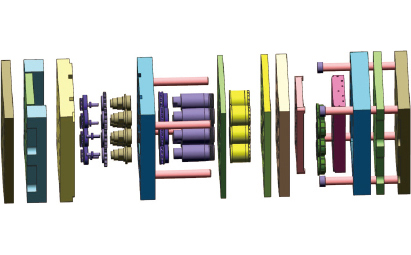

Cap Mould Design

After you confirm the cap drawing, we start make mold design based on the cap structure & your injection molding machine parameters.

04

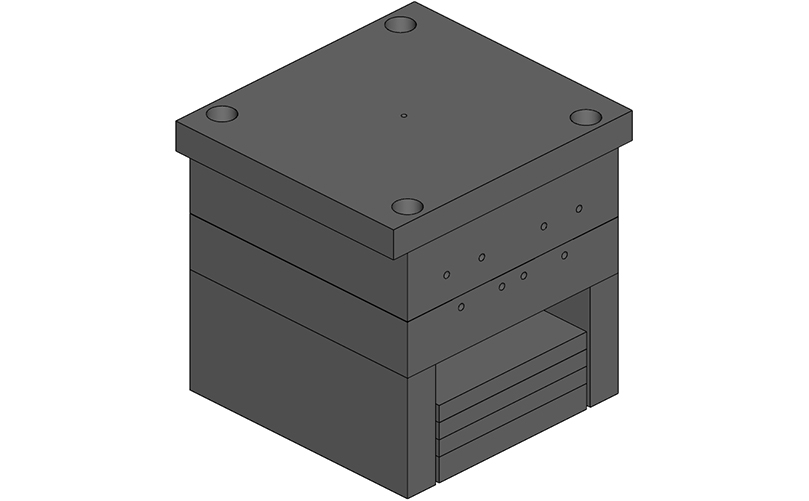

Cap Mould Manufacturing

Next, we start the mold manufacturing. Every detail will be strictly stick to the drawings.

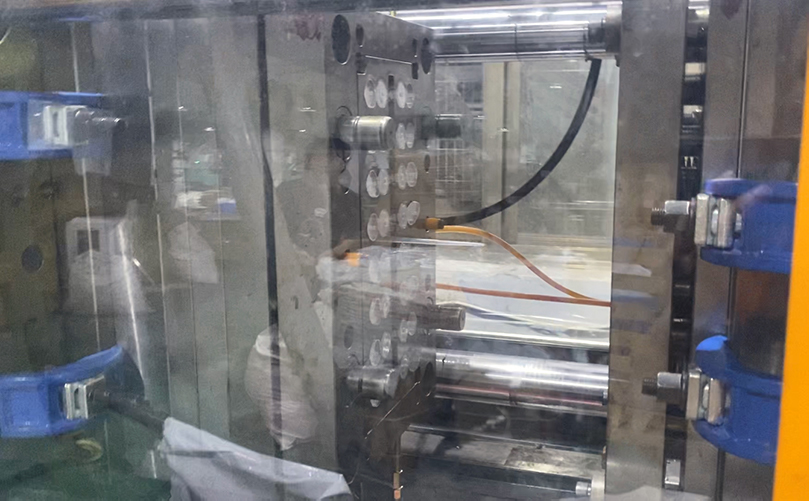

05

Cap Mould Trial

Usually we will do twice mold trial at least. At T0 (first time) trial the main purpose is to test mold movement, parts matching situation and tolerance. At T1 trial, we will keep mold continuous running for 4 hours at least, to make sure everything works properly. If testing works well, we will do the lettering (such as recycling symbol, your LOGO) to the mold and send you real samples for final confirmation. This is where your ideal cap becomes a reality.

06

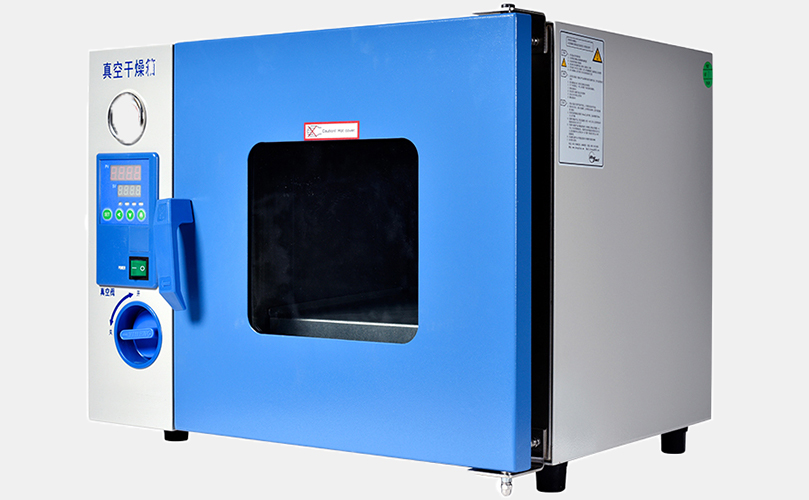

Water Leakage Test

This is a very import process, we will get every cap made from every cavity of mold well tested with Vacuum Leakage Testing, to 100% ensure you will get the perfect caps.

07

Mold Shipping Or Mass Production

The last step is deliver the mold to you. We can provide both of air & sea shipment service for you.

Or if you want the caps only, we can do the mass production for you.

Advanced Cap Mould Design

We constantly incorporate the latest designs into our mould manufacturing, our mission is to contribute to the development of the industry by creating innovation and supply reliable and more competitive products.

Watch this video to see an Advanced Design flip top cap mould we made for our France customer.

The key feature is: closing the cap inside mold during mold running, instead of closing it with another machine or manually.

Basic Specs of Cap Injection Mould

| Mold Cavity Steel: | H13, S136, 718 |

| Mold Core Steel: | H13, S136, 718 |

| Mold Frame: | LKM standard frame |

| Cavity Number: | 2 – 64 cavities |

| Runner System: | Hot runner / Cold runner |

| Hot runner Brand: | Local brand or YUDO |

| Cooling System: | Best cooling water way design. BeCu available as per need |

| Demould Way: | Motor rotating, eject pins, slider, push platen, air gate, force etc. |

| Mold Life: | 1 to 3 million shots guarantee, depends on your needs |

| Delivery Time: | 20 to 70 days as per cap design |

Focused on Manufacturing High Quality Mold

Our focus is the quality. We always listen to the voice of market, our mission is to contribute to the development of the industry by creating innovation and supply reliable products.