Cap liners are integral components in product packaging, ensuring many products’ safety, freshness, and integrity. From food and beverages to pharmaceuticals and cosmetics, these liners offer a tight seal, preventing potential leaks, contamination, and tampering. NABO Plastic provides a variety of cap liners for our plastic caps, including:

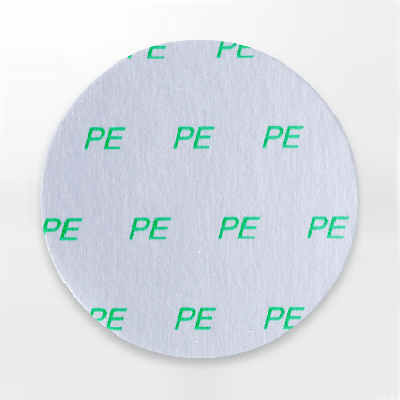

1. PE Foam Cap Liners

Definition:

PE foam cap liners, or Polyethylene foam liners, are a type of cap liner known for their cushioning properties and ability to provide a tight seal.

Manufacturing Process:

Polyethylene resin is injected with liquid carbon dioxide, which possesses specific permeability and compatibility, to serve as a foaming agent. After that, it undergoes further stamping processes to create liners.

Features and Benefits:

- Cushioning Effect: These soft and pliable liners offer a cushioning effect that protects the product from potential damage during transit.

- Moderate Hardness: They are neither too hard nor too soft, striking a balance that ensures excellent sealing.

- Pearlescent Sheen: PE foam liners have a pearl-like luster, making them aesthetically pleasing.

- Hygienic: They are clean, non-toxic, and free from any unpleasant odors.

- Independent Air Pores: These liners have independent air pores, ensuring good chemical stability.

- Resilience: They exhibit good resistance to drugs, water, and acids/bases.

- Moisture and Oxygen Barrier: PE foam liners effectively block water vapor and oxygen, offering excellent moisture resistance and vacuum retention.

- Temperature Resistance: They can withstand temperatures ranging from -25℃ to 121℃.

- Composite Capabilities: They can be combined with various functional films for one-way or two-way composites (see foam overlay series for details).

- Compatibility: PE foam liners can be used with induction aluminum foils.

Applications:

PE foam cap liners are prevalent in packaging food items, cosmetics, pharmaceuticals, and chemicals.

Special Mention:

PE foam liners are the default liner for caps/closures provided by NABO Plastic.

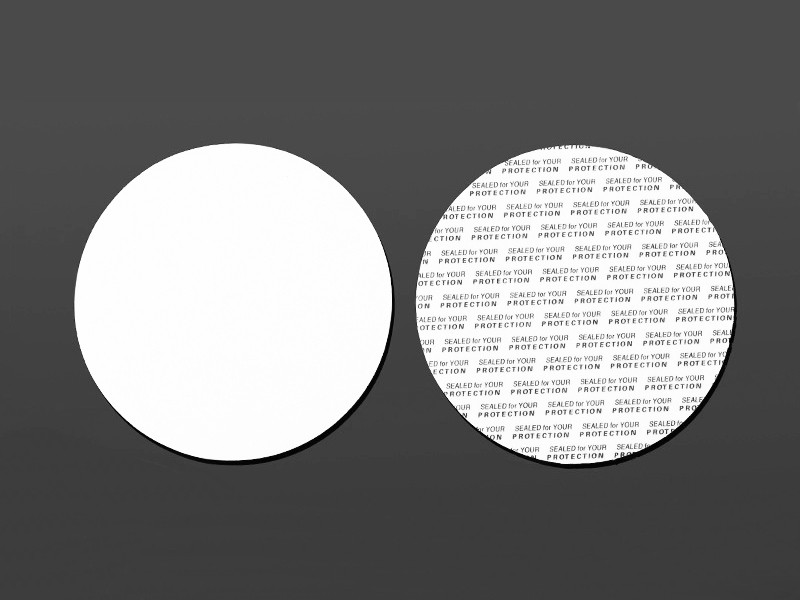

2. Pressure Sensitive Cap Liners

Definition:

Pressure-sensitive cap liners adhere to the container’s rim upon the application of pressure. Their sealing process is straightforward and doesn’t necessitate any specialized equipment.

Features and Benefits:

- Easy Application: Screwing the cap onto the container activates the adhesive, forming a seal.

- Tamper-Evident: The liner remains attached to the container once it’s opened, signaling that the product has been accessed.

- Versatility: These liners are apt for both dry and liquid products.

Applications:

They are predominantly used for food products, pharmaceuticals, and cosmetics, especially when tamper evidence is paramount.

3. Heat Induction Cap Liners

Definition:

Heat induction cap liners are affixed to the container using an induction sealing machine. This machine generates an electromagnetic field, inducing heat in the liner’s foil layer, which melts the sealant, bonding it to the container’s rim.

Types of Heat Induction Liners:

Heat induction liners are primarily classified based on the type of bottle/container material they are designed to seal with. Here are the main types or classifications of heat induction liners:

Heat Induction Liners for PE Bottles/Containers

Designed to create a seal with polyethylene (PE) bottles/containers (commonly used in the food and beverage industry).

Heat Induction Liners for PET Bottles/Containers

Tailored for polyethylene terephthalate (PET) bottles/containers (widely used for packaging foods and beverages, especially bottled water).

Heat Induction Liners for PP Bottles/Containers

Meant for sealing with polypropylene (PP) bottles/containers (often used for packaging yogurt, margarine, and other dairy products due to their moisture barrier properties).

In addition to these primary classifications, heat induction cap liners can also vary based on:

One-Piece Heat Induction Liners

One-piece liners form a seal directly with the container when heat is applied.

Two-Piece Heat Induction Liners

Two-piece liners, on the other hand, have an additional wax layer and a secondary backing, which separates from the foil layer after sealing, leaving behind a secondary reseal liner.

Heat Induction Liners with Pull Tabs

Some liners include pull tabs to make it easier for consumers to remove them.

Features and Benefits:

- Leak-Proof and Tamper-Evident: They offer advantages such as leak prevention, theft deterrence, and counterfeit protection.

- Easy Opening: No tools are required for opening; consumers can easily peel them off by hand.

- Consumer-Friendly Design: They can incorporate “corner protrusions” or “semi-pull tabs” for consumer convenience.

- Clean Removal: After peeling, the bottle mouth remains residue-free.

- Customization: Personalized branding or markings can be provided on the liners.

Applications:

Heat induction cap liners are widely used for dairy products, beverages, pharmaceuticals, and chemicals that necessitate a robust, tamper-evident seal.

To sum up, cap liners are pivotal in product packaging, offering protection, ensuring freshness, and providing evidence against tampering. The choice between PE foam, pressure-sensitive, or heat induction liners hinges on the specific needs of your product and the desired level of protection. Always opt for the appropriate cap liner to uphold the quality and safety of your product.

| Cap Liners Type | Thickness | Diameter |

|---|---|---|

| PE Foam Liner | 0.5 – 4 mm | 5 – 140 mm |

| Pressure Sensitive Liners | 0.6 – 2.0 mm | 5 – 140 mm |

| One-Piece Heat Induction Liner | 0.25 – 0.3 mm | 5 – 140 mm |

| Two-Piece Heat Induction Liner | 0.6 – 1.2 mm | 5 – 140 mm |

| Heat Induction Liner with Tabs | 0.25 – 0.3 mm | 5 – 140 mm |